We have been keeping the world moving since 1964

As the world's largest supplier of products for high-performance motion plastics, we at igus® have the required experience to sustainably change urban mobility through the use of plastics.

PARTNERS WANTED

“We are empowering an industry to produce sustainable, maintenance-free and durable bicycles from recyclable materials.”

'Tech up, Cost down' - materials from igus are manufactured according to this motto. Our products are designed to extend the service life of machines and applications, eliminate maintenance work and reduce costs. We know that high-performance plastics can have a positive contribution to the protection of resources and environment and this has become the focus of our entrepreneurial activities. We continuously research and develop in the field of full-motion plastic applications (motion plastics) - for the environment, for progress and for a better tomorrow.

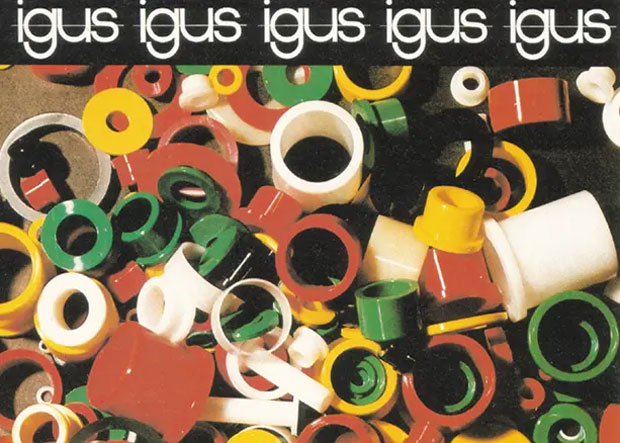

WE ARE IGUS

Our trademark: Over 55 years of experience in the field of motion plastics

1964

Founding of igus GmbH

Günter Blase founds the company igus together with his wife Margret in a garage. In 1965, the first product made of plastic is already produced by injection molding: A valve cone for vehicle carburetors.

1983

The foundation for later innovations

The company's first plain bearing material called iglidur G is presented at the plastics trade fair 'K'. The all-round classic is still in the product range today.

1990

First use on the bike

The motion plastics technology is used for the first time in a full-suspension mountain bike in the USA - the foundation stone is laid.

2009

A far-reaching vision

On the Atlantic Beach in North Florida, the idea for a bicycle made of plastic is born. Inspiration: The high-maintenance, classic rental bikes of the hotel. After the vacation, the search for partners begins.

2019

Strong alliances

With brothers Johannes and Benjamin Alderse Baas and their company mtrl, they are found. The Dutchmen already build rental bicycles that consist of a high proportion of plastic. They join forces and Frank Blase, CEO of igus, becomes an investor in mtrl.

2021

The development: focus on sustainability

Both companies are now concentrating on increasing the proportion of plastic in the joint prototype. igus supplies know-how and production in the area of moving parts, mtrl is responsible for frames and wheels.

2022

A revolution rolls onto the stage

The first prototype of the igus:bike plastic bicycle is ready and is now being used as a showcase by customers, at trade fairs and at igus itself. Research and development are intensified, the team around the bicycle grows.

2023

Development is progressing

The prototypes of frames and components are tested, optimised and given the finishing touches. The proportion of recycled frame material is now 50%. Development is so far advanced that the first 100 bikes will be produced at the beginning of 2024.

FUTURE OF THE IGUS:BIKE

The know-how platform for plastic bikes

The platform is aimed at both end customers and companies: Bicycle customers can see what the state of the art is and where they can buy plastic bikes. We offer bicycle and component manufacturers the opportunity to drive forward modern mobility together with us.

The platform is intended to become a contact point for bicycle manufacturers around the world, where the status and progress of all components is continuously shown. We would also like to explicitly invite competitors to join us on this path – major changes are only possible faster if we work together.

Interested manufacturers can use the platform to gain an initial overview, benefit from the know-how already built up, or network with each other. Our vision is to provide a point of contact that effectively helps manufacturers.

DISCOVER IGUS:BIKE

Meet the first all-plastic bike from mtrl

Introducing a bike innovation for urban mobility: This bike is made of recycled high-performance plastic. It does not rust and requires almost no maintenance - sustainable plastics moving people.

What the bike can doWHAT OUR EMPLOYEES SAY

Our attitude, our demand

“The igus:bike opens completely new doors. This allows us to offer bicycle developers as well as producers a variety of new ideas and solutions”

Andreas Hermey

RESEARCH & DEVELOPMENT E-CHAINS

“Who wouldn't wish to be able to maintain a bike without lubricants and thus keep clean hands?”

Lena Wölke-Glomb

MATERIAL DEVELOPMENT XIROS

“The vision is that the world's plastic waste dumps will become valuable resources for bicycles.”

Frank Blase

CEO IGUS

“With the igus:bike, you save valuable maintenance time thanks to the high-performance plastics used. Above all, a bicycle gearbox made mainly of plastic was unthinkable for a long time.”

Michael Otrebowski

RESEARCH AND DEVELOPMENT DRYLIN

SUSTAINABILITY IN PRODUCTION

Climate neutrality by 2025: Our big step toward a green future

We at igus have made the aspect of sustainability the focus of our corporate activities. By 2025, we want our buildings and production to be CO₂ neutral. Find out what else we are up to.

Sustainability at igusPARTNERS WANTED

Do you want to be part of something big?

We are looking for strong corporate partnerships to help us make our vision of producing sustainable, maintenance-free and durable bicycles from recyclable materials a reality. If you would like to enter into a collaboration with us or place a press inquiry, we look forward to hearing from you.

Contact us now